Ball Nosed Cylinder-C Diamond Grinding Head-Cutting Tools

Item Photo

Item Basic Details

Advantage: 1. Diamond material, not easy to deform. 2. Less dust, more environmental protection. 3. High manganese steel, thickened matrix. 4. The reinforcing rod is designed to prolong the service life.

Item Name: Diamond Grinding Head

Item Model: Ball Nosed Cylinder-C

Head Material: Diamond

Item Application:

1. The mold part is ground and polished.

2. Grinding: generally used for grinding the burr of workpiece, or machining the surface of workpiece with low precision Use grinding machine, electric, pneumatic and other tools to operate at high speed to achieve the grinding effect.

3. Polishing: it is specially used for processing with high requirements for surface finish (roughness). It is a process requiring separate processing.

Head Diameter: 6mm/8mm/12mm/14mm/16mm/18mm/20mm

Head Length: 27mm

Shank Length: 33mm

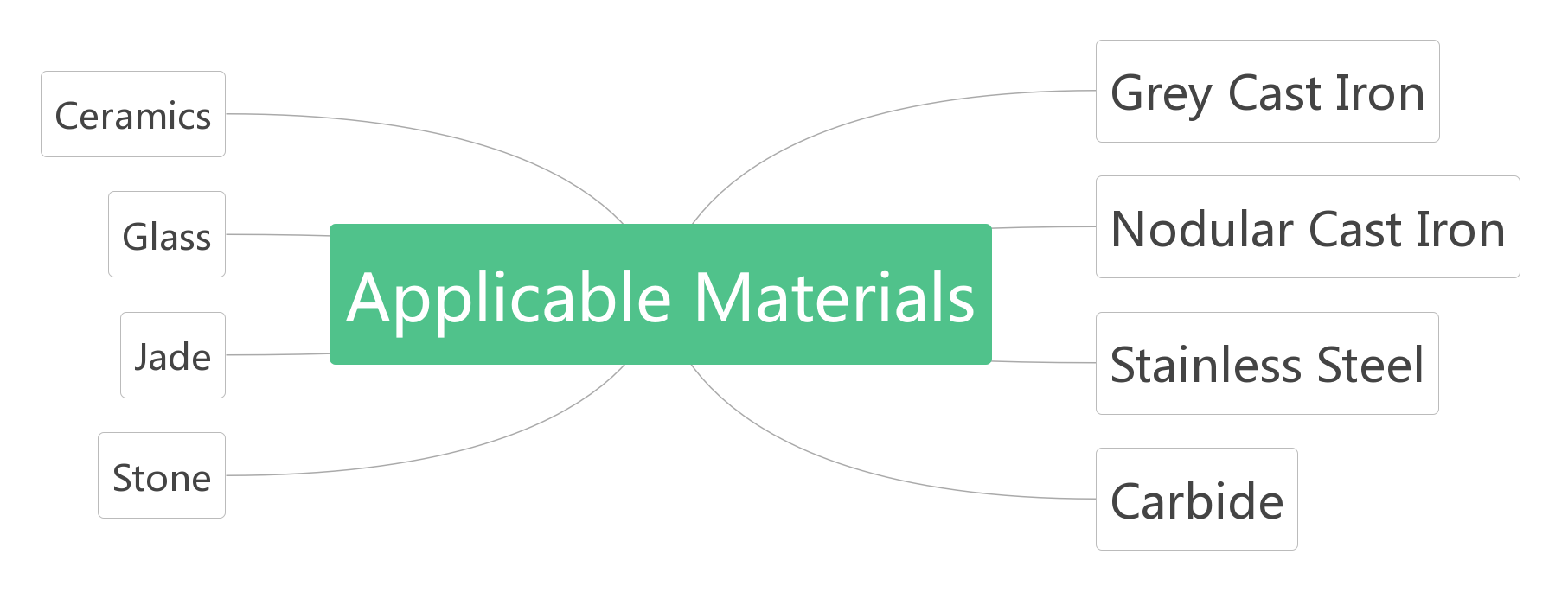

Item Applicable Materials

Item Application

1. Stone processing

2. Glass processing

3. Dressing grinding wheels, refractory materials, cement products

4. Use for grinding, polishing and grinding6.The mold part is ground and polished

5. It is generally installed in grinders, grinders, polishers, or special installation tools. It is widely used in optical lenses, prisms, watch glass, sapphire glass.

Item Dimensions

|

Model |

Diameter |

Total Length |

Working Length |

Shank Length |

Shank Diameter |

|

Ball Nosed Cylinder 6*6 |

6mm |

60mm |

27mm |

33mm |

6mm |

|

Ball Nosed Cylinder 6*8 |

8mm |

60mm |

27mm |

33mm |

6mm |

|

Ball Nosed Cylinder 6*10 |

10mm |

60mm |

27mm |

33mm |

6mm |

|

Ball Nosed Cylinder 6*12 |

12mm |

60mm |

27mm |

33mm |

6mm |

|

Ball Nosed Cylinder 6*14 |

14mm |

60mm |

27mm |

33mm |

6mm |

|

Ball Nosed Cylinder 6*16 |

16mm |

60mm |

27mm |

33mm |

6mm |

|

Ball Nosed Cylinder 6*18 |

18mm |

60mm |

27mm |

33mm |

6mm |

|

Ball Nosed Cylinder 6*20 |

20mm |

60mm |

27mm |

33mm |

6mm |

Applicable Scenario

Product Comparison

Brazing grinding head

● Long service life, more durable than ordinary grinding heads

● Less dust, more environmentally friendly

● Sharp grinding and high efficiency

● High manganese steel, thickened matrix

Traditional grinding head

● Short service life, uneven stress will produce deformation

● The dust is large, causing harm to human body

● Short service life, manual replacement is time-consuming and laborious

● Ordinary material handle, easy to break, poor balance

Product Advantage

1. We are professional carbide burr manufacturer since 1992. With 30 years of grinding product of experience.

2. We will strictly test all products.

3. All products are in stock.

4. We provide free shank logo and free label on product.

Diamond Grinding Head Advantages

1. High grinding efficiency:

When grinding cemented carbide, its grinding efficiency is several times that of silicon carbide. When grinding W12 cr4v4mo, a high-speed steel with poor grinding performance, the average efficiency is increased by more than 5 times.

2.High wear resistance:

Diamond grinding wheels have high wear resistance and low abrasive consumption, especially when grinding hard and brittle workpieces. When grinding quenched steel with diamond grinding wheel, its wear resistance is 100~200 times that of general abrasive;

3. The grinding workpiece has high precision and good surface quality

When grinding cemented carbide tools with diamond grinding wheel, the roughness of the blade surface and blade is much lower than that with borax carbide wheel. The arc radius of the blade is small, and the blade is very sharp. The durability of the tool can be increased by 1~3 times. The roughness of workpiece processed by diamond grinding wheel can generally reach 0.1~0.025 μ m. Compared with ordinary grinding wheel grinding, the finish can be improved by 1~2 levels.