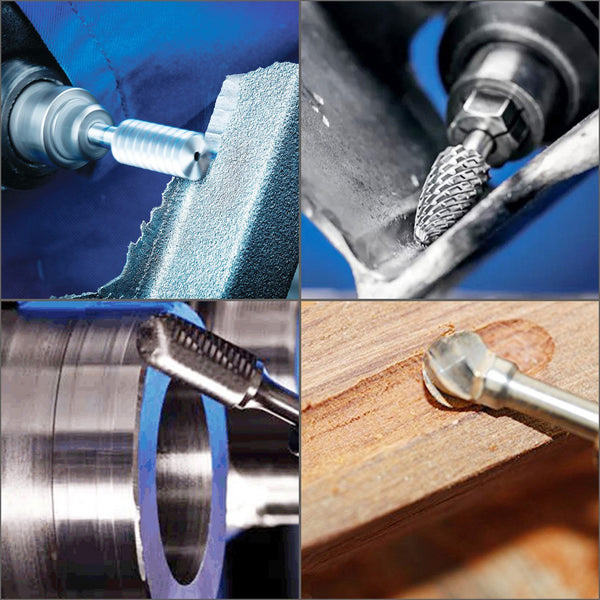

Use of carbide burrs:

Tungsten carbide rotary file is widely used in machinery, automobile, shipbuilding, chemical industry, craft carving and other industrial departments, the effect is remarkable, the main uses are:

(1) finishing all kinds of metal mold cavity, such as shoe mold and so on.

(2) all kinds of metal and non-metal craft carving, craft gift carving.

(3) flanges, burrs and welds of machined casting, forging and welding parts, such as machine casting factory, shipyard and automobile factory.

(4) all kinds of mechanical parts chamfering chamfering and groove processing, cleaning pipes, finishing mechanical parts of the inner hole surface, such as machinery factory, repair shop and so on.

(5) The repair of impeller runner parts, such as car engine factory.

Main features of rotary file:

Cemented carbide rotary file has the following characteristics:

(1) Any metal (including hardened steel) and non-metallic materials (such as marble, jade, bone) below HRC70 can be machined at will.

(2) It can replace small grinding wheel with handle in most work, and no dust pollution.

(3) High production efficiency, dozens of times higher than the processing efficiency of manual file, nearly ten times higher than the processing efficiency of small grinding wheel with handle.

(4) Good processing quality, high finish, can process a variety of high-precision mold cavity.

(5) long service life, durability is ten times higher than high speed steel tool, durability is more than 200 times higher than alumina grinding wheel.

(6) Easy to use, safe and reliable, can reduce labor intensity, improve the working environment.

(7) The economic benefit is greatly improved, and the comprehensive processing cost can be reduced by tens of times.

CNC machine manufacturing and hand manufacturing:

Of course, there are still some manufacturers who still make rotary files by hand, and their products are very irregular when used.

Prone to trembling, blade fracture, wear and other phenomena, resulting in a lot of inconvenient operation. While the CNC machine produces the rotation.

The main parameters of the file, such as groove depth, groove width, groove concentration, cutter Angle and spiral Angle, have high stability. The result, of course, is that the latter is more convenient to operate, run more smoothly, the processing effect is better, and the most effective overall.

Post time: Jun-21-2022