Wood chisels are tools used for cutting, carving, or gouging on wood. Proper material selection and usage skills can enhance the effectiveness and lifespan of wood chisels. Here are some suggestions for wood chisel material selection and usage skills:

Material selection:

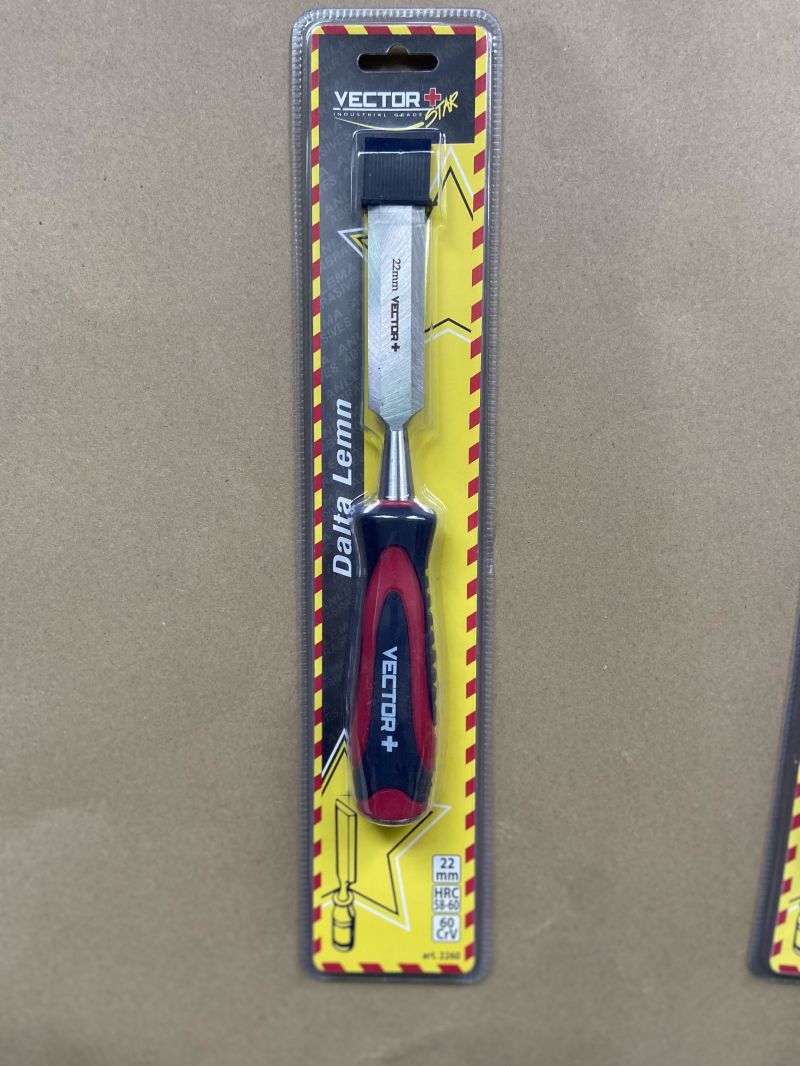

1. High-carbon steel: High-carbon steel is a common material for wood chisels, offering good strength and durability. It is suitable for most types of wood, especially hardwoods and high-density woods.

2. High-speed steel: High-speed steel is a material with excellent hardness and heat stability. It is often used for handling harder woods or situations that require high-speed cutting.

3.Tungsten alloy: Tungsten alloy is an extremely robust and wear-resistant material used in the manufacturing of high-quality wood chisels. It is suitable for working with hardwood, plywood, and composite materials.

The hardness of a wood chisel depends on the material it is made from. Wood chisels are typically made from high-carbon steel, high-speed steel, or tungsten alloy, which have different hardness levels. Here are some approximate hardness ranges for these materials:

1. High-carbon steel: High-carbon steel used for wood chisels typically has a hardness ranging from 55 to 62 HRC (Rockwell Hardness Scale). This level of hardness allows the chisel to maintain a sharp edge and resist wear during use.

2. High-speed steel: High-speed steel used for wood chisels is known for its exceptional hardness. It generally has a hardness range of 62 to 67 HRC, providing increased edge retention and resistance to heat and wear.

3. Tungsten alloy: Tungsten alloy chisels are extremely hard and durable. They typically have a hardness range of 65 to 70 HRC or even higher. The high hardness of tungsten alloy ensures excellent cutting performance and extended tool life.

It's important to note that the exact hardness of a wood chisel may vary depending on the specific brand, manufacturing process, and heat treatment applied to the tool. Always refer to the manufacturer's specifications or consult product information to determine the hardness of a particular wood chisel.

Usage skills:

1. Maintain sharpness: Sharpness is crucial for the cutting performance of wood chisels. Regularly inspect the chisel blade and use a sharpening stone or grinder to maintain sharpness.

2. Control cutting force: When using wood chisels, apply moderate cutting force and avoid excessive pressure. Excessive force can cause the chisel to get stuck or damage the blade. Use gentle pushing and twisting motions to smoothly advance the chisel blade through the wood.

3. Precise positioning: Before starting the chiseling, mark the desired cutting location using a ruler, pencil, or marking tool. Ensure that the chisel blade starts cutting from the correct position for accurate results.

4. Select the appropriate chisel shape: Wood chisels come in various shapes, such as flat chisels, round chisels, and square chisels. Choose the chisel shape that suits the specific task requirements for optimal results.

5. Use a mallet: For tasks that require more force, you can use a wooden mallet to assist with the chiseling. Gently tap the handle of the chisel to drive the blade into the wood, but be careful to control the force and avoid excessive pounding that may cause damage.

6.Safety precautions: Always prioritize safety when using wood chisels. Ensure the wood is securely fixed to prevent slipping or accidental injuries. Additionally, wear appropriate personal protective equipment, such as eye protection and gloves, to safeguard yourself during operation.

Post time: Jun-09-2023