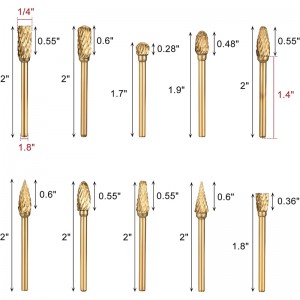

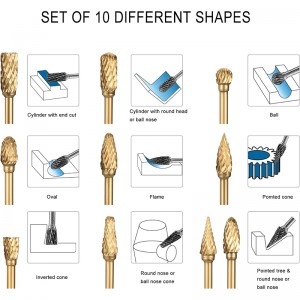

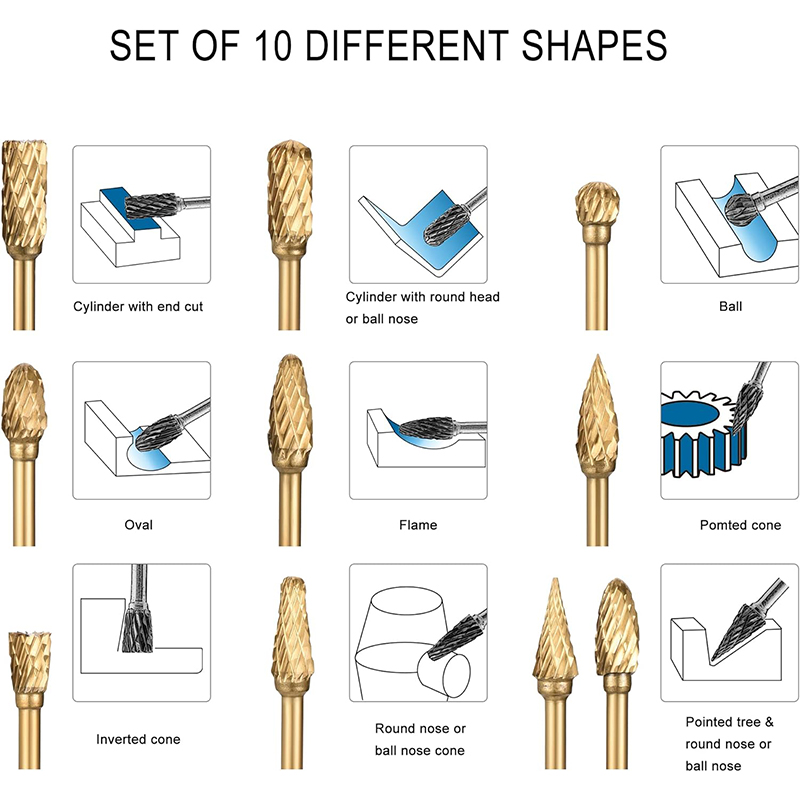

sa-5 6mm 10pcs rotary burr set tungsten carbide rotary burr

About Us

Established in 1992, Leading Supplier of carbide burrs

Main product: all kinds of carbide burrs with silver brazing(single cut, double cut and Alu cut)

Machine: 5 axis linkage cnc machine which can make accuracy of cut higher

Mission: Supplying excellent removal solution to various industrial sectors such as foundries, aerospace, shipbuilding, automobile and so on

Main Clients: Shipyard like Samsung

Delivery time: Most types we have stock ready to ship

Features of tungsten carbide burr

PLAIN CUT

--THE GENERAL USE OF ∞ PLAIN CUT ± IS ON STEELS, STEEL ALLOYS, CAST IRON, COPPER AND BRASS.

--DESIGNED FOR RAPID STOCK REMOVAL AND GOOD WORKPIECE FINISHES.

--PRODUCES LONG CHIPS.

DOUBLE CUT

--THE DOUBLE CUT BURR ALLOWS RAPID STOCK REMOVAL IN THE HARDER MATERIALS

--DESIGNED FOR CREATING A SMALL CHIP AND EXCELLENT WORKPIECE FINISHES

--THE SMALL CHIP HELPS TO ELIMINATE LOADING OF THE FLUTES

--EXCEEDINGLY CONVENIENT APPLICATION BY USER.

ALUMA CUT

--DESIGNED TO HAVE WIDER CHIP SPACE WITH RELIEF ANGLE

--MORE SUITABLE APPLICATION TO NON-FERROUS METALS.

Carbide Burr Set

Shipping: The cost quoted is EXW without shipping

MOQ: 50pcs each type, total above 500Pcs

Delivery time:carbide burrs 10 to20days

Payment: TT or Credit card from alibaba

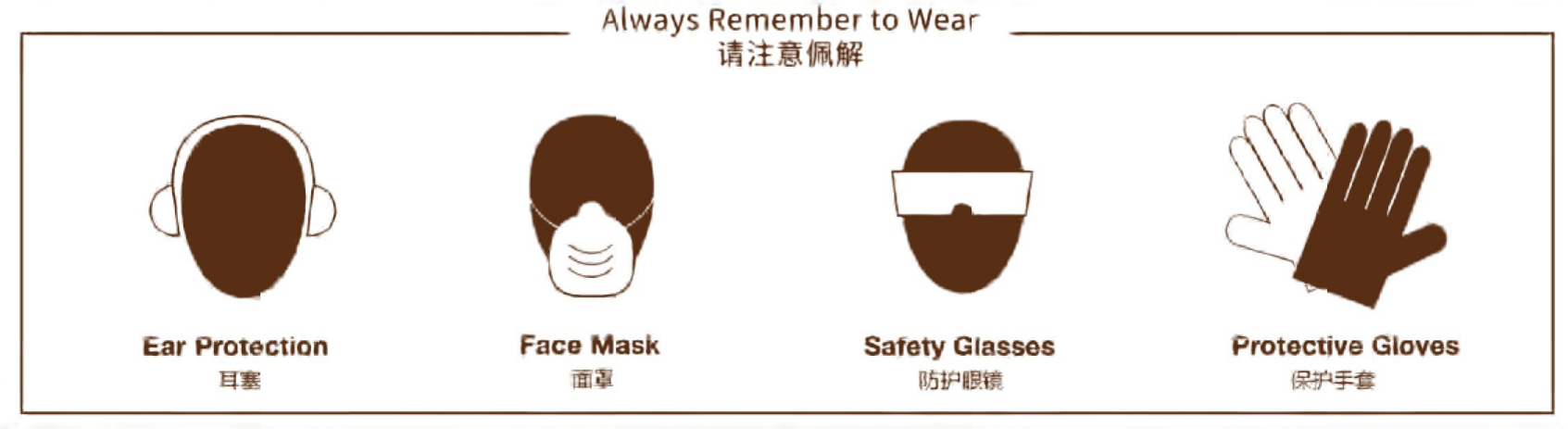

Please pay attention

Always operate the burr within the recommended speeds guide.

Always ensure the appropriate tool is used and that tis regularly maintained.

Alwaysfix the maximum length of burr in the collet.Do not exceed the recommended maximum over hang. Long shank burrs require slower running speeds.

Always use a smooth cutting action with constant movement in both directions.

Don't Run burr above the maximum operating speed,this can cause premature tooth wear.

Don' t run a burr too slowly, this can cause chipping.

Don't Sink the burr to more than one third of its periphery. Do not encapsulate.

Don't Allow burr to become too hot, this may cause the braze to soften and cause the head to become detached from the shank (only applies to burrs where head diameter is greater than the shank diameter).